There’s no doubt that Woven furniture is one of the most popular styles for UK garden furniture. Almost every garden in the country has some form of woven furniture in it, but where did the trend start? This blog is going to take you through the interesting history of how this style of furniture manufacture was introduced and how it took over the garden furniture industry.

Firstly, is it important to understand the distinguishing terminology. Wicker is a type of weaving and rattan is a material, these two terms are often interchanged but actually mean different things. Wicker is a term that comes from Scandinavia. It is believed to derive from the terms ‘wika’ which translates as ‘to bend’ and ‘vikker’ which means ‘willow’. Rattan is an umbrella term for natural fibres which includes over 600 different species of plant fibres, native to tropical forests in Indonesia, Southeast Asia, and the Malay Archipelago. We at Alexander Rose use the term weave to describe our wicker furniture. Our furniture is made from a high-quality and durable synthetic polymer, therefore we do not use the term rattan to describe it.

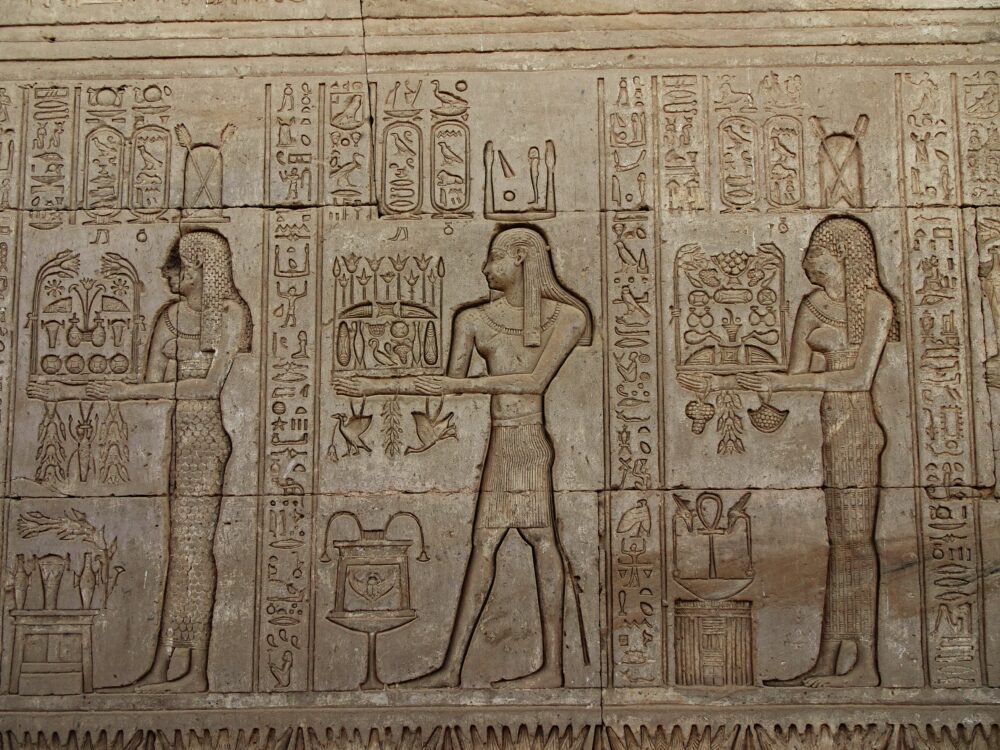

Ancient Rattan

We can thank the Ancient Egyptians for wicker furniture. Wicker furniture including chairs and stools were discovered alongside pharaohs in their tombs. This woven furniture was made out of grass and cane that grows naturally in that area of Africa. The art of wicker spread into the Roman Empire, facilitating the wider dissemination of the process.

Introduction to the New World

Fast forward to the 1600s and the intrepid voyage of the Mayflower which brought colonial expansion to North America. It was a time for many new discoveries, but most people would be unaware that this journey brought wicker furniture over to North America in the form of a baby’s basket. What the passengers at the time could have never known is how this one piece of furniture led to the remarkable success of the industry hundreds of years in the future.

Lloyd Loom

Although wicker furniture arrived when Europeans first set foot in America, the style didn’t take hold for a few hundred years. In Menominee, a city in Michigan, a factory was making waves with a revolutionary new furniture innovation which was introduced to the British market in 1922. ‘Neither cane nor wicker – superior to either’ Lloyd Loom was about to explode onto the scene. An innovation in the manufacture of wicker meant that Lloyd Loom could create wicker furniture cheaper and faster than any methods that had been used before. Before the development of Lloyd Loom most people could not afford to purchase wicker furniture, which was manufactured from relatively expensive materials and woven by highly skilled professionals.

The innovation was simple, effectively Lloyd Loom used twisted paper to create a strong, durable and flexible material. It’s biggest advantage was that it had a very similar appearance to traditional wicker furniture. In modern times we would probably describe this as ‘faux-wicker’ and the market responded very well.

1960s – 70s

The 1960s and 70s saw a huge revival for wicker furniture. Before this, Victorian-style furniture was seen as overly-sophisticated and therefore in fashion. Then people began to introduce wicker back into their homes. This could have been due to Gabriella Crespi, interiors style icon, as she showed how it could be used to fuse cultures and design movements to bring a space new life. Gabriella managed to blend haute bourgeois taste with modern design, using natural materials such as bamboo and rattan.

21st Century

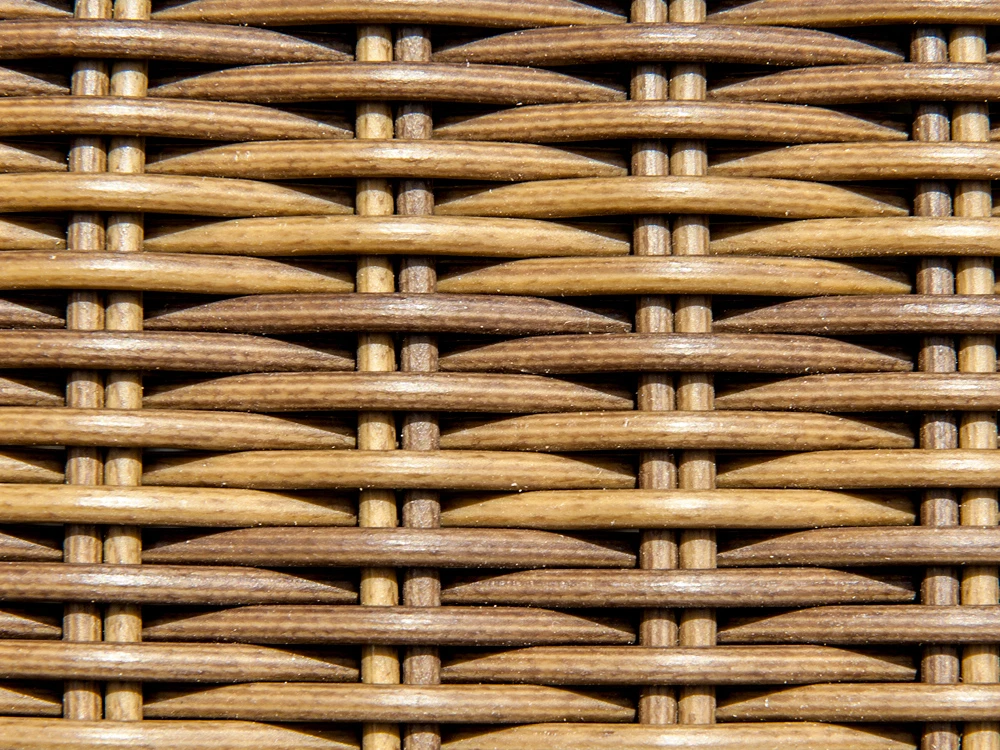

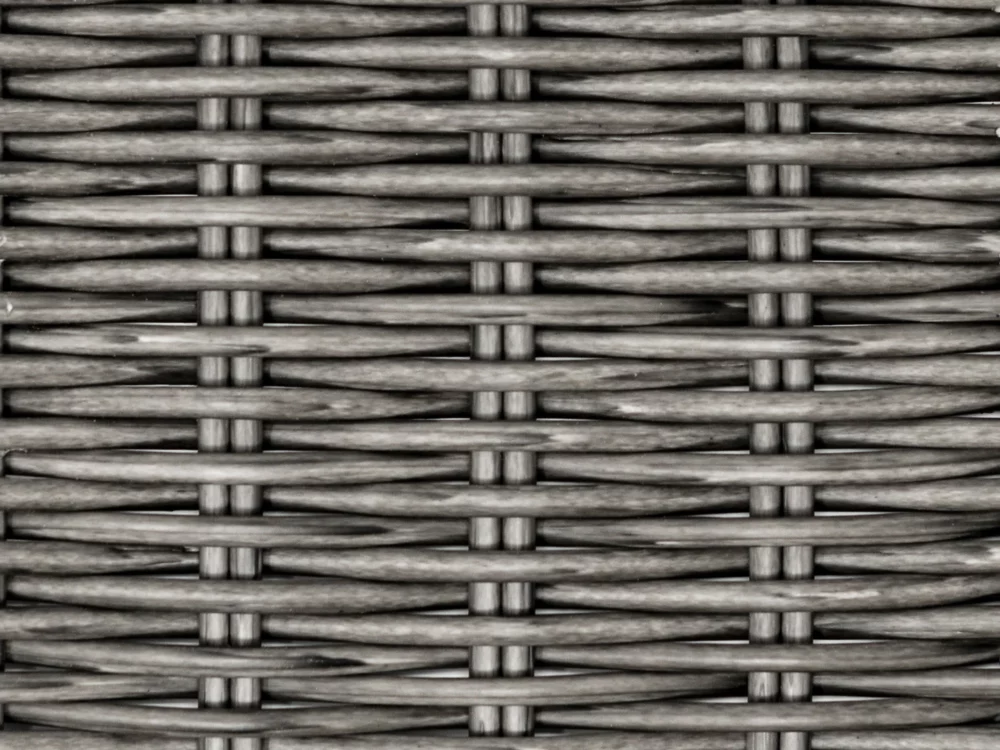

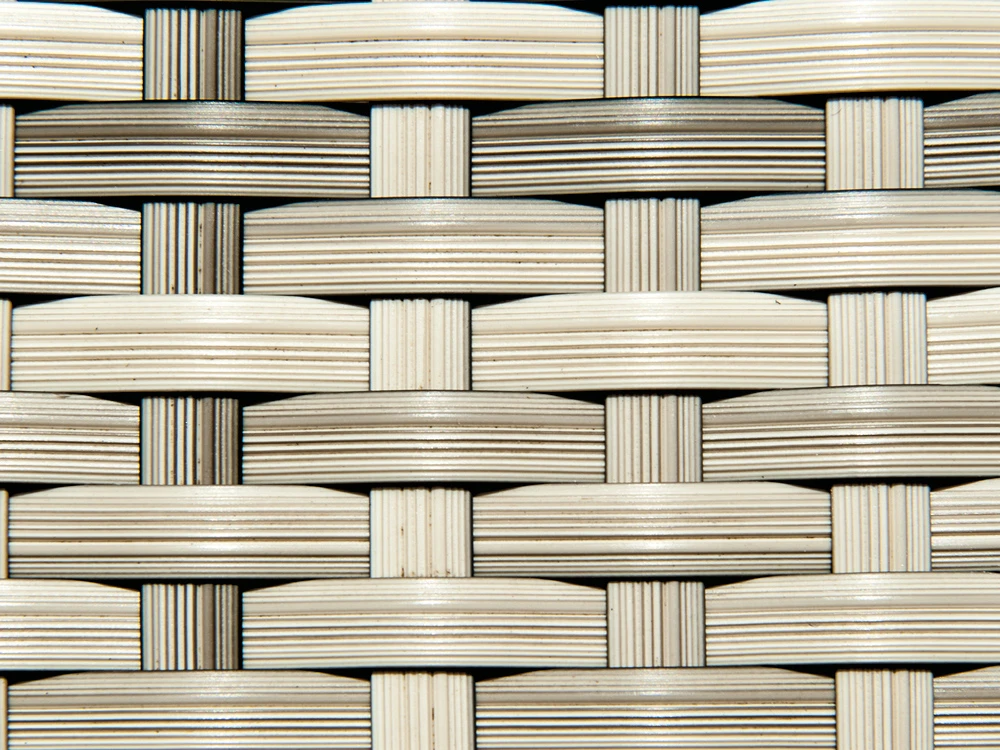

In the 21st century wicker furniture has become a cornerstone of outdoor and indoor living. Advancements in technology have meant woven furniture can be made faster, stronger and in a vast array of colours and textures. Wicker furniture has certainly had its ups and downs in terms of popularity, but it seems it has become more stable in terms of style. Much like the teak dining table or the leather sofa, pieces that will likely stay in fashion for decades, I believe the same can be said for wicker-style furniture. Our three weave ranges are a testament to that, ranging from huge daybeds to small sleek coffee tables. We specialise in woven furniture – employing contemporary manufacturing methods to blend classic shapes to create products with a timeless appearance.

In the mid-2000’s the synthetic resin wicker that we use at Alexander Rose became popular as a commercial-grade product. Furniture made from this synthetic material can be left outside all year round without cracking and fading. It is perfect for busy hotels and restaurants as it is practically maintenance free and can be cleaned easily, and its colourfastness and durability means that it will stay looking the same for many years to come.

How is it made?

Wicker is a weaving process that starts with a frame. In our case, the frame is aluminium, chosen for its strength, weather resistance and lightweightness making it the perfect skeleton for weave furniture. The frame starts as a straight length of metal before being bent around a form and welded together. Once the frame is built it is then treated to improve the finish on the metal. Our factory uses a powder coating method which provides an even and textured finish to the aluminium. Once the frame has been built and finished it is time to start the weaving process.

How is it maintained?

Our woven furniture is very easy to maintain. A soft-bristled brush can be used to remove any accumulated dust or dirt. If you have any slightly more stubborn stains our furniture can be washed using warm soapy water and a sponge, or even jet washed on a wide setting.

Alexander Rose’s 3 weave ranges for 2023

We have consolidated our weave ranges to the three most popular offerings – San Marino, Monte Carlo and Ocean Pearl.

Facts:

- A typical Alexander Rose woven armchair takes 20 hours to weave and uses 830 linear metres of 3mm round Rose Fibres, which is 2m greater than the Burj Khalifa.

- Rose Fibres are UV tested for 2000 hours using Xenon lamps to reproduce accelerated weathering and extreme sunlight conditions. Colour assessment tests are carried out on the Grey Scale with a rating of 1 to 5; a rating of 1, would show the greatest colour change, with 5 showing no change; Rose Fibres have a rating of 5.

- Elongation and breaking strain tests are applied through the fibre until destruction. A 2m length of Rose Fibre (3mm round section), will break at a tension of 14kg/31lb. Lesser quality fibres tend to break at 7kg/15lb. This is a sign of the high-quality material that makes stronger longer lasting furniture.

- Rose Fibres are 100% recyclable and all wastage is reused to make plastic components, such as feet for chairs.

By Ed Fairfax